The tool then rotates where the friction between the shoulder and the seam softens the metal.

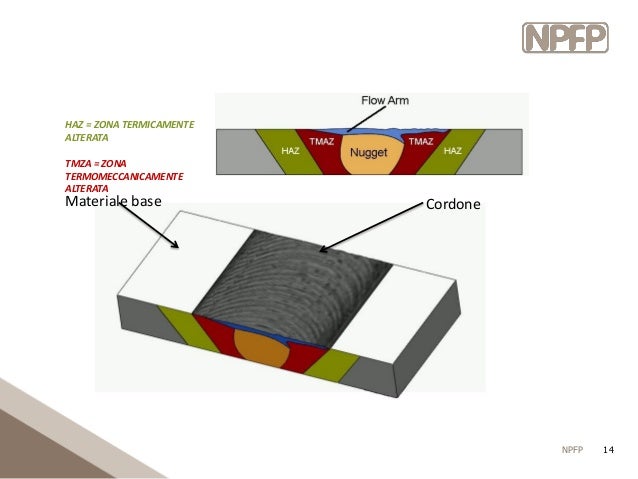

The pin drives along the seam of the two workpieces until the shoulder rests on the seam. The resulting heat generated at the surfaces causes the metal to plasticize, and the oxides or surface-level contaminants are burned off or expelled at the sides.įriction Stir Welding: Friction stir welding uses a special tool with a cylindrical shoulder and a profiled pin to create welds. Linear friction welding: In this type of friction welding, one of the materials oscillates in relation with the other at high speeds with high compressive forces in a reciprocating motion. This combination causes the plasticizing of the two materials, eventually leading to a bond between the two. The process uses compressive axial force and the high rotation speeds. Rotary Friction Welding: Out of the two materials, one is rotated over the surface of the other where the weld is required. Let's go through each of them briefly to understand the subtle differences between them. However, there are four types of friction welding processes fundamentally. Different types of friction weldingĪny welding process that uses friction as a way to create the bond can be termed as friction welding. As the process continues further, the heat generation also rises, and the two materials will start becoming viscous at the contact points.Īgain, the motion between the two promotes the mixing of the two parts at their contact points, creating a bond or a weld. When two materials undergo friction welding, the relative motion between each other, and the pressure applied to them generates heat at the contact points.

These irregularities are enough to generate friction between their surfaces. Even if the two materials to be welded together may seem smooth to the naked eye, there are irregularities at the microscopic level. This interaction between the two surfaces results in mechanical friction. The same principle of heat generation by friction is used in friction welding, where the metal parts are made to rub against each other at extremely high speed and pressure. As you increase the pressure and speed further, you will start feeling warmer. If you rub your palms against each other, you’ll observe that your palms will become hot. RELATED: LASER WELDING: TYPES, ADVANTAGES, AND APPLICATIONS The process of friction welding

Let’s get into the details of how this technique works and its benefits.

0 kommentar(er)

0 kommentar(er)